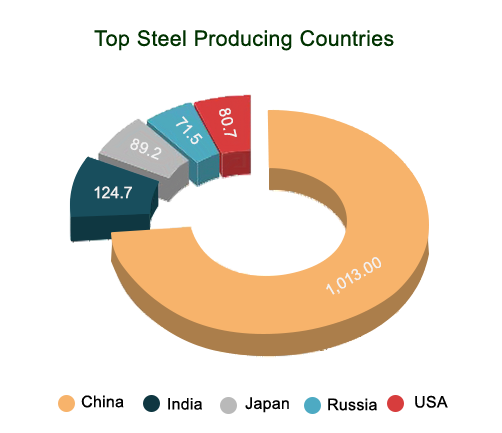

One of the primary forces behind industrialization has been the use of metals. Steel has traditionally occupied a top spot among metals. Steel production and consumption are frequently seen as measures of a country's economic development because it is both a raw material and an intermediary product. Therefore, it would not be an exaggeration to argue that the steel sector has always been at the forefront of industrial progress and that it is the foundation of any economy. The Indian steel industry is classified into three categories - major producers, main producers, and secondary producers.

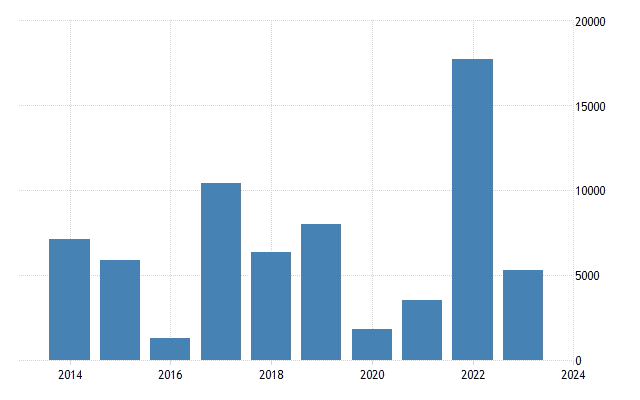

India is the world’s second-largest producer of crude steel, with an output of 125.32 MT of crude steel and finished steel production of 121.29 MT in FY23.

India’s steel production is estimated to grow 4-7% to 123-127 MT in FY24.

The growth in the Indian steel sector has been driven by the domestic availability of raw materials such as iron ore and cost-effective labour. Consequently, the steel sector has been a major contributor to India's manufacturing output.

The Indian steel industry is modern, with state-of-the-art steel mills. It has always strived for continuous modernisation of older plants and up-gradation to higher energy efficiency levels.

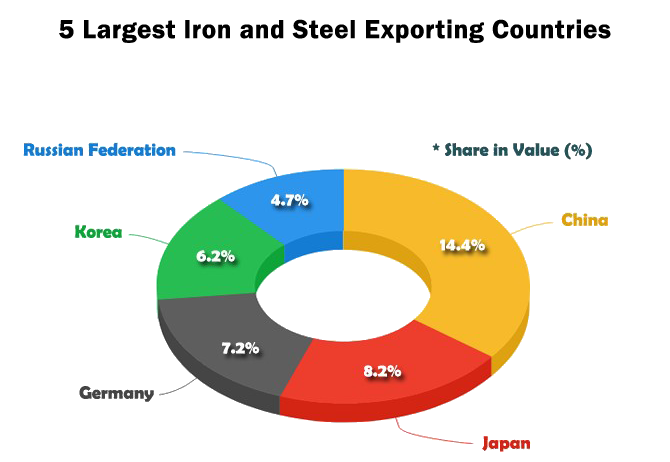

Key components used in the production of machinery, autos, appliances, and other industrial goods include iron and steel. The pricing and availability of iron and steel are directly related to the state of the industrial industry. India imports iron and steel from a number of nations.